Project Objectives

To tackle the worldwide challenge of climate change, this project aims to decarbonize the oil and gas industry by implementing a novel approach to reforming methane and producing hydrogen without generating carbon dioxide.

This innovative technology has the potential to enhance energy security while also providing environmental and economic benefits. The project focuses on developing scalable methods for preparing highly active, recyclable, and stable catalysts to produce hydrogen via Hydrogen Sulfide Methane Reformation (H2SMR). Our approach offers a valid alternative for the simultaneous valorization of hydrogen sulfide and hydrogen production at an industrial scale.

The primary objectives of this project are threefold: (1) to address the issues of hydrogen sulfide in oil and gas fields, sour gas sweetening, and flaring, (2) to reform methane and produce low-cost hydrogen without direct carbon dioxide generation but with carbon disulfide as a feedstock for the petrochemical industry, and (3) to improve the efficiency and sustainability of catalytic reactions to reduce the cost of hydrogen production to €0.80 per kg in Europe. By achieving these objectives, this project will contribute significantly to the global effort to mitigate climate change by reducing carbon emissions and promoting sustainable energy practices.

Our Motivation

In order to reform methane with hydrogen sulfide (a highly toxic and corrosive substance), the stability and durability of catalysts are of utmost importance. Currently, catalysts become poisoned and deactivated within just a few minutes, which increases both the cost and time required for this process. Mesoporous-supported nanocatalysts, which possess a high surface area and permeable porous structure, are able to hold a large amount of accessible small-sized nanocatalysts. Due to their unique physiochemical properties and novel preparation methods, these catalysts remain highly stable under high temperatures and pressure, as well as during iterative reactions. These characteristics result in efficient catalytic reactions and enhanced catalytic activity.

Over the past few years, we have been conducting laboratory-based research into the strategies and designs of mesoporous catalysts with the aim of improving the efficiency and sustainability of hydrogen production. Through our self-funded efforts, we have successfully developed “nanocatalysts supported on mesoporous boron nitride” that are highly stable. This achievement has enabled us to investigate an improved Hydrogen Sulfide Methane Reformation (H2SMR) process by developing stable and low-cost catalysts that are capable of supporting large-scale production and innovative separation methods.

Furthermore, the integration of Non-Thermal Plasma (NTP) with the boron nitride catalyst can substantially improve the process efficiency and ensure catalyst longevity. PIs have considerable practical experience in the design, fabrication, and testing of plasma-chemical reactors, in general, and dielectric barrier discharge, in particular.

We can help who?

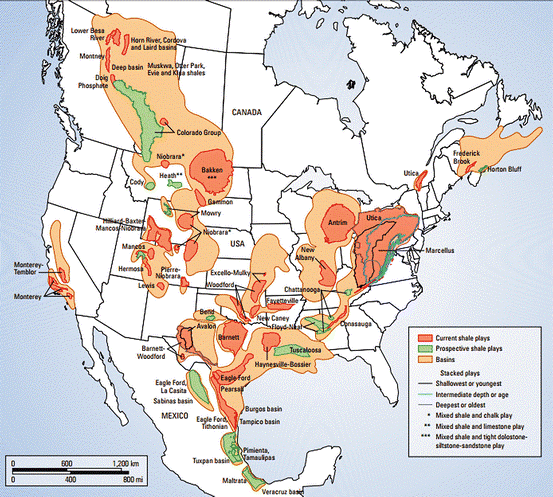

The Persian Gulf is one of the candidates where there are many sour gas fields with a high percentage of H2S (>5%) and low-cost methane. However, due to the high development costs and the risks associated with the elevated H2S presence, these gas fields are abandoned and new development concepts are required for economic exploitation. Another region is North America (e.g., Alberta, Saskatchewan, and British Columbia) where unconventional oil/gas fields produce a high amount of H2S (>10%). Alberta, Canada is a large producer and consumer of H2 generated from steam methane reformation [4]. During the upgrading and refining of sour crudes, H2S is generated as a by-product of hydrotreating processes. H2 production via H2SMR may enable the recovery and recycling of H2S, significantly reducing the need to access new H2 resources and reducing costs.

Also, our technology could help the biogas process industry. During biogas production, hydrogen sulfide (H2S) can be produced as a byproduct. The presence of hydrogen sulfide in biogas can be problematic for several reasons and to mitigate these issues, biogas producers often employ various techniques to remove hydrogen sulfide from the biogas. H2SMR process could eliminate hydrogen sulfide content and make the biogas suitable for various applications, such as energy generation or use as a fuel source, and simultaneously reform a part of biomethane to hydrogen.

Nouvelle-Aquitaine (France) and Lower Saxony (Germany), where there are many gas reservoirs with a high percentage of H2S, are the first regions targeted for the realization of the pilot project. The largest onshore gas field in Europe, the Lacq gas field in southern France is a candidate for the pilot project. TotalEnergies and Geopetrol produced natural gas for years and still, some wells are in operation with the objective of producing H2S for players in the highly developed chemical industry in Lacq and for some R&D projects like the oxy-combustion project.